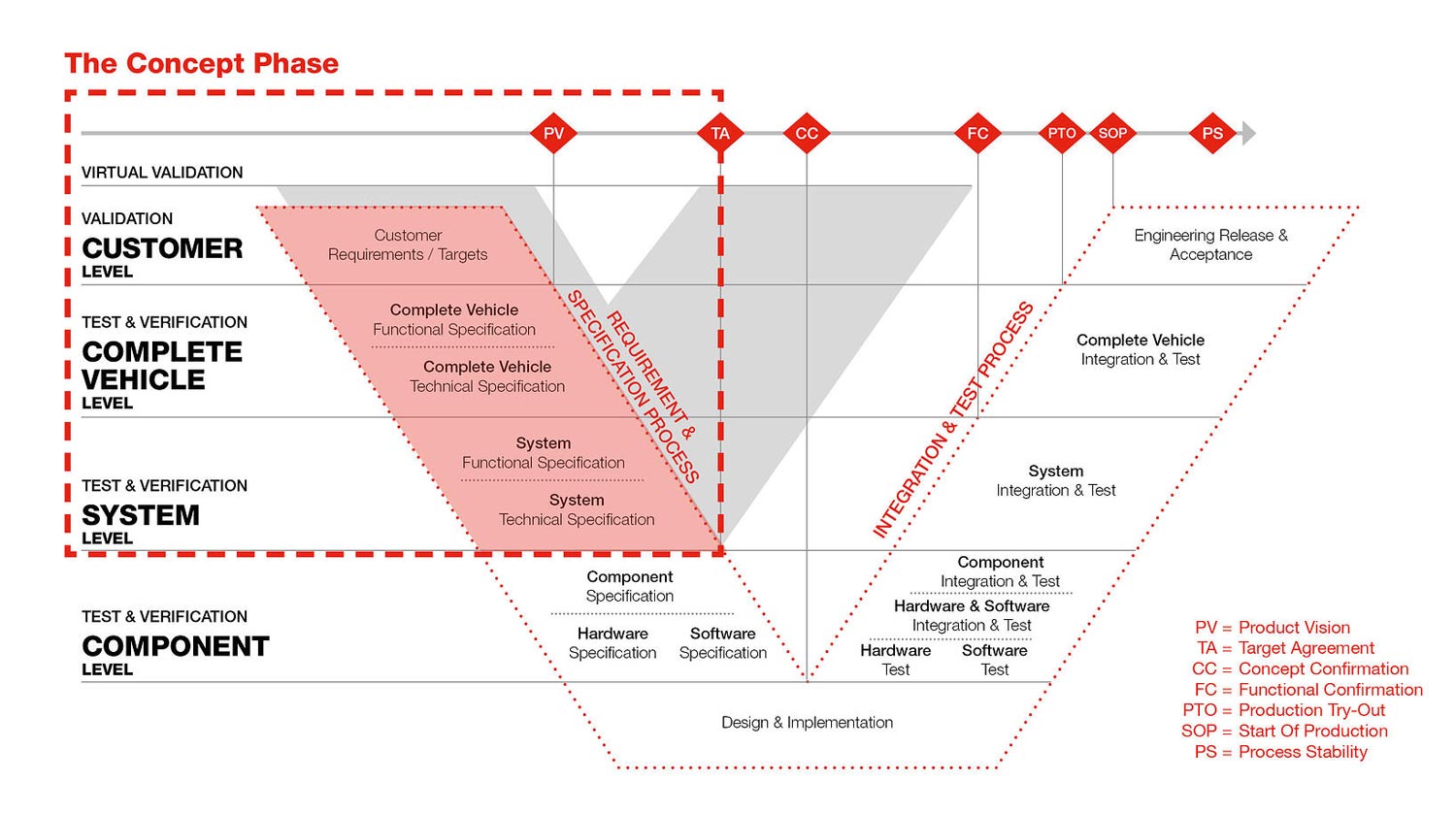

The concept phase includes the upper left segment of the V-model. The goal of the concept phase is to verify the key technical and economic targets as well as the overall time frame of the project.

This phase starts with the creation of the Customer Market Profile (CMP). With the CMP created, the target market and benchmark vehicles defined, the first complete vehicle targets can be established with the first set of measurable metrics.1

Once the complete vehicle targets are clear, they are further broken down into system-level targets. This process is marked by intense cooperation between interdisciplinary teams, as features all overlap into multiple systems and changes in one area often impact a multitude of other areas.2

Two key documents are created within the concept phase: the product requirement specification book(s), which show the tasks and resources for system or component suppliers, and an initial bill of materials (BOM), which lists all resources needed to calculate the business plan for the complete vehicle.

Both documents will be continuously detailed and updated throughout this development phase as the vehicle concept becomes more sophisticated.

With the requirements, specifications and the rough BOM at hand, the vehicle targets can be agreed upon in the target agreement (TA). Once the TA has been reached, the set requirements and metrics are definitive and serve as the basis for the upcoming development phase.

In addition, the business case is updated based on the technical input with focus on the investments (tooling, plant, supplier development cost, …).

HOW DO YOU ENSURE A SMOOTH PROJECT PROCESS?

Several challenging situations can occur during the concept phase. The following five strategies will help in navigating the concept phase.

1. Assume That Your BOM Needs Re-Adjustments

The bill of materials is one of the most common pitfalls for new entrants. The initial BOM is devised during the concept phase, and thus based on estimations. Therefore, it will be incomplete in some segments. As the project progresses, the BOM will thus require adjustments to the initial estimates or the addition of parts missing in the original draft. Even minor alterations to the project can change the calculated cost for the business plan. Therefore, new entrants should monitor changes during the concept phase constantly and ensure a clear decision-making process.

2. Keep Design and Engineering in Balance

The main point of interaction in vehicle development usually forms between the technical features of a vehicle and its design and styling concept. Technical requirements sometimes limit the creative freedom, whereas design choices demand compromises from the technical architecture. Close cooperation and mutual understanding between the technical teams and stylists helps to find the best balance.3

3. Use Simulation and Virtual Testing

It is important to already start the validation of the vehicle concept in a very early stage of project development to assess whether the vehicle targets can be accomplished. This is achieved with virtual technologies in the testing and validation processes.

By using virtual development methods, the time-to-market and development cost can be optimized. Thanks to virtual tools and simulation methods, the prediction quality of digital prototypes is very advanced. As such, a high level of design maturity can be achieved, even in this early project phase.

For example, with vehicle safety there are numerous requirements and standards – from legal requirements and consumer ratings such as NCAP and IIHS - to market and technology trends such as new electric platforms and automated driving. This may lead to new challenges in passive safety and crash worthiness. Body construction meets those demands with various material combinations and hybrid joining technologies. For this, high prediction quality and efficiency of simulation methods are very important. However, achieving both factors require constant comparison between simulation and measurements.

Virtual tools can facilitate this process considerably. Small joining elements are first tested physically before the results of these tests are implemented into a complete vehicle simulation. This way, results can be obtained more easily and quickly and with higher accuracy. Correct interpretation of the results is most important for successful simulation, perhaps more than the right software tools.