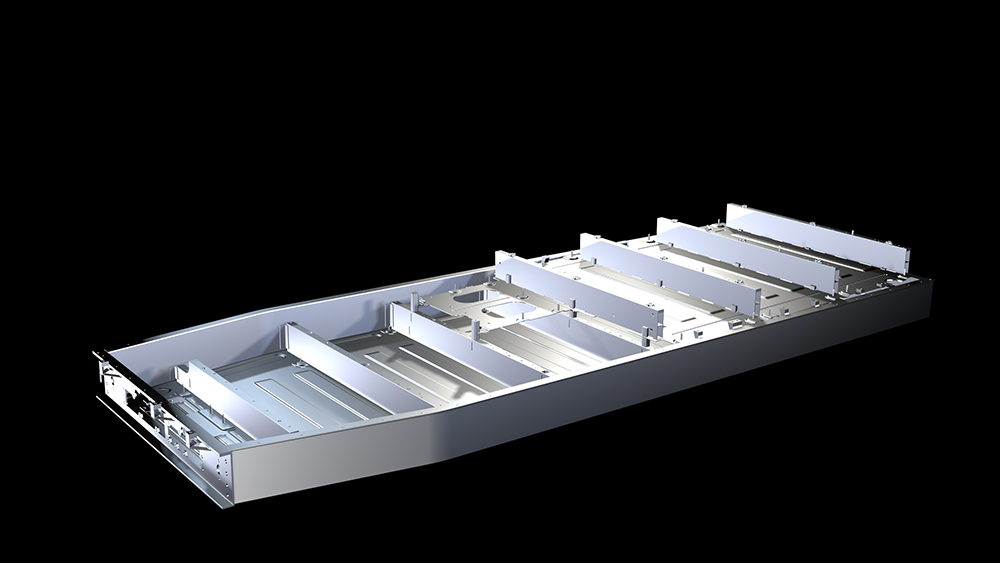

Precision is the key when it comes to making this complex automotive subsystem that requires intricacy and high standards of craftsmanship. It’s like bringing the demands of making a Swiss watch into a part that can be larger than a kitchen table.

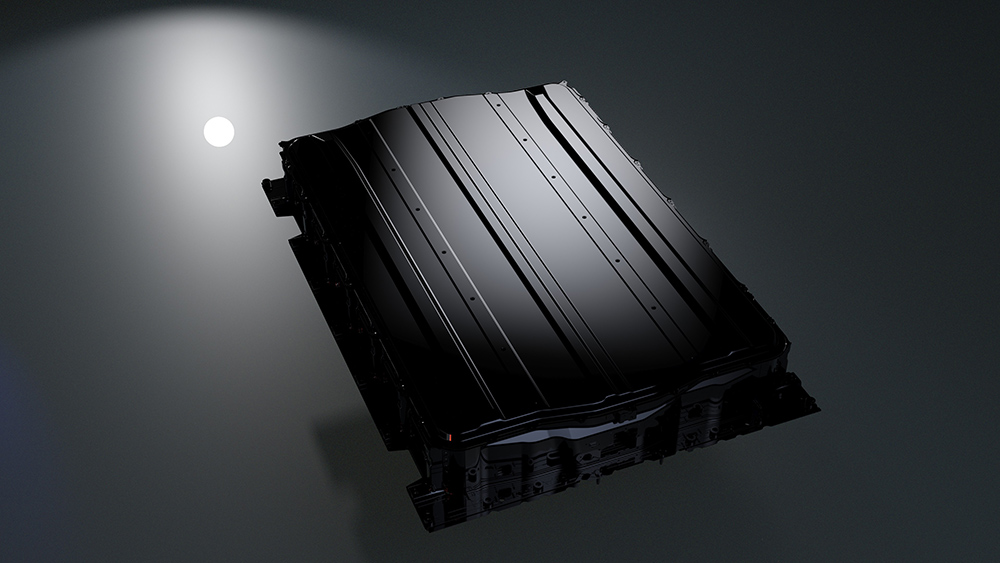

But unlike a timepiece or a clock, consumers may never see the battery enclosure because it is hidden on the underside of the vehicle. Most importantly, the battery enclosure is a critical element of every EV, contributing to the structural and safety aspects of the vehicle and protecting high-voltage batteries from damage and water.

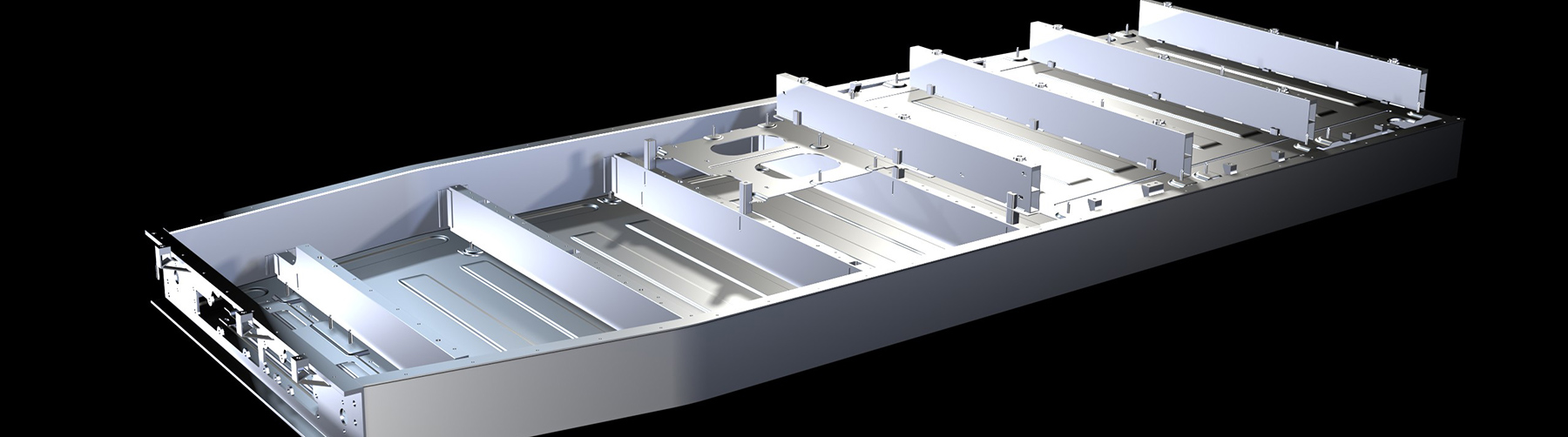

At our St. Clair plant, we’re making two versions of the steel battery enclosure for the Hummer EV, designed to fit the short- and long-wheelbase versions of the truck. Both are packed with parts, including stampings, roll-formed components and fasteners. The integration and assembly of all these components into such a large assembly held to millimeter-level tolerances is a challenge that we have overcome.

Our expertise and innovative processes enable battery enclosures to be developed in steel, aluminum and multi-material configurations, including lightweight composites, to meet the individual needs of each customer. Because of our ability to adapt to customer requirements, Magna is widely regarded as a technology leader in the shift to electrification.

We have our eye on the future and further evolving the design and integration of the battery enclosures into the structure of the vehicle.

Magna’s full systems approach, in-depth product expertise and complete vehicle knowledge enable us to see the big picture and deliver the innovations that drive the future of mobility.

Photo gallery

We want to hear from you

Send us your questions, thoughts and inquiries or engage in the conversation on social media.

Related Stories

Magna Recognized as 2024 Supplier of the Year and Over Drive Award by General Motors

Releases

Stay connected

You can stay connected with Magna News and Stories through email alerts sent to your inbox in real time.