Complete Vehicle Engineering

Engineering Excellence Every Step of the Way: From the Initial Brief to Final Release.

Global OEMs and New Entrants value Magna’s unique combination of comprehensive vehicle engineering expertise and a deep knowledge of all aspects of vehicle manufacturing.

We can offer a comprehensive range of engineering services, from individual tasks to full engineering support, and from derivatives to developing completely new vehicles from scratch. Magna works together with its customers to deliver a huge variety of engineering projects, and can draw on years of experience meeting the specific needs of customers all over the world.

Our product portfolio

Take the 360° virtual tour for exclusive insights into our engineering facilities!

Design & Vehicle Concepts

Designing the Vehicles of the Future

Vehicle Feasibility Studies

Magna can scout trends affecting multiple products and conduct global product-related market analysis, as well as producing technical product analysis and comparisons. These studies then form the basis for full technical feasibility studies and complete vehicle concepts. We have years of experience in delivering innovative designs, so you can rely on us to turn your idea into a solution that works – complete with an attractive business case.

Design Concepts

Every one of our designs starts with a blank sheet of paper and a pencil. This initial sketch is crucial, because it shows the character and essence of the end product. Whether your brief is for a futuristic, retro, sporty or elegant design, our designers will skillfully combine surfaces, volumes, and shapes to create something exceptional. Our highly-skilled team can come up with a whole new design language from scratch, at the same time as incorporating, interpreting or developing the customer’s own approach.

Vehicle Concepts

As demand for mobility grows, consumer requirements are becoming ever more diverse. As a leading automotive supplier, we face the challenge of these requirements head on. Our solutions can help you access new niches, shorten development times and product cycles, and deliver effective platform strategies to achieve more modularization and design freedom.

Complete Vehicle Engineering & Integration

Solutions to Get Industry Excited

Engineering Your Project Every Step of the Way

At Magna, when we develop a vehicle, we start from the customer’s market profile and technical objectives. Once these objectives are clear, we design systems and modules to deliver them. We can draw up the overall development strategy and deal with every stage of the development process, including virtual modelling and physical testing for all the vehicle’s functionality and features. We are committed to delivering all the features you need, as well as unbeatable reliability.

Virtual development

Processes & Methods

As market conditions change, companies need a global outlook, a clear understanding of their customers’ requirements, and the expertise to deliver those requirements cost-effectively. This means their processes need to be agile and efficient. Our in-house product development process makes full use of state-of-the-art processes and methodology, including validated simulation procedures as well as Digital Factory and Smart Factory systems. These cutting-edge solutions provide maximum quality, safety and flexibility for our customers.

Software

Integrating Alternative Propulsion Systems

The Right System for Your Electric Vehicle

Whether it’s climate change or mobility change, the automotive industry is constantly on the move. Legal frameworks and a growing market demand are playing a major role in the further development of alternative drive systems. Electrification is also making it easier for new players to enter and shape the market, introducing innovative ways of developing and implementing drive systems.

Magna has many years of experience with alternative propulsion systems – 30 years in alternative powertrains alone, along with 20 years in hydrogen powertrains. The drive system is designed with the complete vehicle in mind, both in terms of complete vehicle development and in sub-projects.

Complete vehicle integration – tailored to your needs

We provide our customers with a turnkey product: starting with the selection of the propulsion system and the evaluation of suppliers, through to the definition of the specifications, to integration into the vehicle, and the verification and validation of all functions. No matter whether it’s a complete EV, hybrid, or hydrogen vehicle or sub-project.

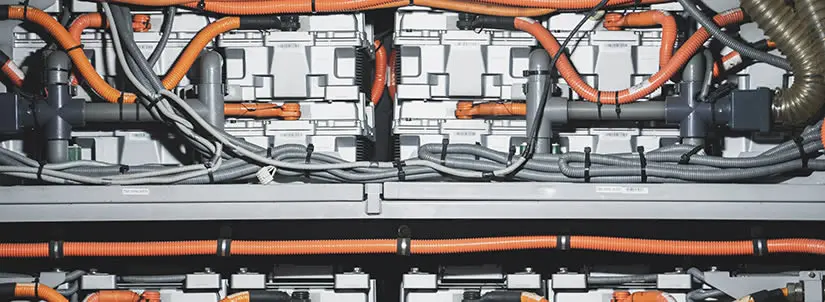

Thermal management

Smart thermal management combines the utmost passenger comfort with the best possible driving range – even in extreme weather conditions.

Our experienced team integrates the thermal management system into the complete vehicle. We also implement the measurement equipment on component and system levels. Finally, we conduct extensive vehicle and system testing – both on test benches and on the road.

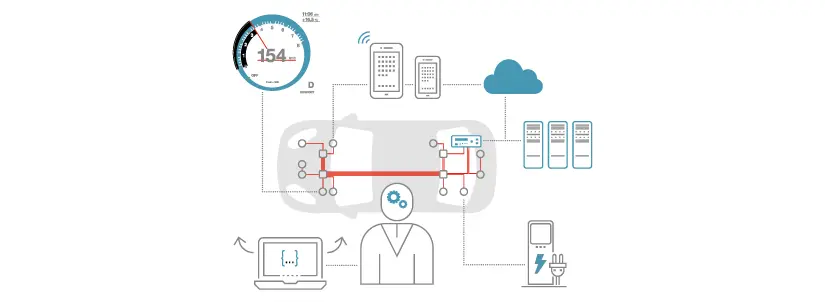

Vehicle control unit

Our VCU, which we have developed in-house, serves as the heart of an electric drivetrain. This central control unit is responsible for controlling the vehicle dynamics by providing and supervising the driver’s commands to the motor and the high-voltage battery.

Our VCU supports advanced vehicle dynamics by distributing torque between the front and rear axles, as well as different charging standards. It also includes thermal management for the high-voltage components and can be driven by a number of different bus systems.

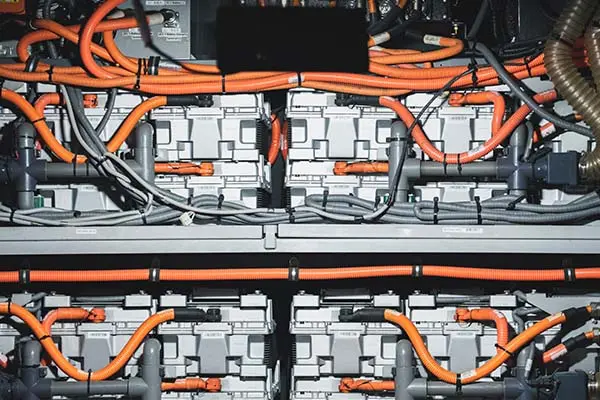

High-voltage battery development and testing

Everything from a single source – we develop, integrate, and validate high-voltage batteries from feasibility to SOP.

We define the cells and models and create the electric, cooling, and housing design. We use state-of-the-art tools to conduct thermal, stiffness, durability, and crash simulations.

What’s more, we conduct DV/PV testing as well as crash and EOL testing in dedicated facilities.

Charging solutions

Quick and easy charging is the key to making it suitable for everyday use. Magna is an experienced partner for the entire user charging experience.

We support our customers throughout the entire development process. Our engineers develop smart charging functions (such as Plug & Charge, V2X or WEVC) and integrate them into the complete vehicle.

Our HMI departments can supply tailormade operating concepts for charging to ensure an unparalleled customer experience.

Integrating Functionality & Features

The Advent of the Software-Defined Vehicle

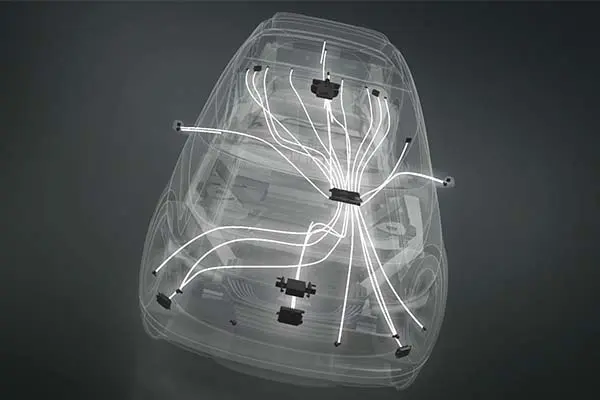

Electric and electronic systems are increasingly vital components of all modern vehicles, and the number of user-focused and internal systems is constantly increasing. With this in mind, integrating these systems into vehicles requires even more specialized skillset. Magna has the expertise required to design and build complete E/E architectures, as well as to integrate and secure complex systems.

Electrics & Electronics

In today´s vehicles, electrics and electronics are increasingly important. The share of comprehensive customer- and system functions increases continuously. In this context, the total vehicle understanding is an important part in the competence of the functional Integration. We have the competence to design entire EE architectures as well as to integrate and secure complex systems.

Integrating Advanced Driver Assistance and Human-Machine Interfaces

The complex and dynamic nature of vehicle electrical and electronics systems requires a high level of expertise in systems networking and machine interfaces. At Magna, we are working on the electrical and electronics architectures of the future. Our primary focus is complete vehicle integration and validating both semi- and fully-automated driving systems. Our work covers testing strategies and maneuver catalogues for individual systems and vehicles, as well as ensuring compliance with active safety requirements.

Advanced Driver Assistance System Integration

Equipping your vehicle with a cutting-edge ADAS system

The future is digital and automated - also for mobility. As a result, infotainment and user experience will become increasingly important. Automation must be able to keep pace with this development because end customers expect an ever-greater choice of features. Advanced Driver Assistance systems not only have a practical value, but also serve to create recognition and differentiation from the competition. Whoever sets the tone here can win the market.

Magna builds not only on many years of experience in integrating and validating Advanced Driver Assistance Systems, but also on the cooperation with its own HMI department. As a full-service provider, Magna thus offers both a competent supplier network as well as the complete infrastructure and access to all relevant testing facilities.

Full-service supplier for ADAS integration

Magna can provide you with customized overall packages as well as specific individual solutions. We cover the entire spectrum including step-by-step planning regarding the complete vehicle and Advanced Driver Assistance Systems, as well as benchmarking, requirement management, system supplier management and finally the complete integration of software and hardware. Magna can also take care of testing and validation - both virtually and on test benches (hardware-in-the-loop) in the early development phase and with the vehicle on test tracks and public roads.

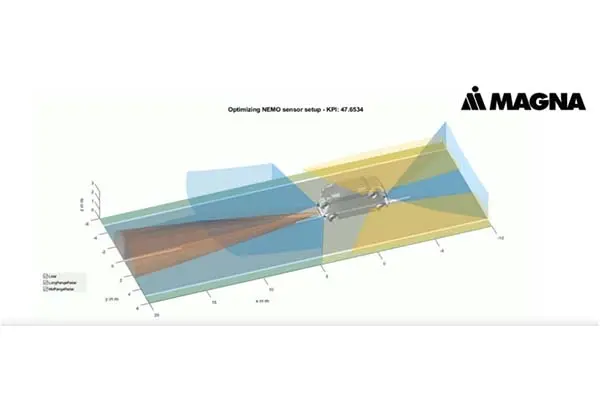

Virtual Sensor Integration

Integrating ADAS sensors into the complete vehicle requires close alignment with the styling department. Virtual methods, such as our Sensor Integration Tool, help to find a good balance between optimal sensor positions and the desired styling from an early development phase on.

ADAS tests for homologation, consumer ratings and benchmarking

While ADAS features have become essential for consumer ratings and vehicle homologation alike, they are also a major brand differentiator. Compliance with all relevant standards and a great customer experience requires thorough complete vehicle testing of ADAS functions.

We plan and conduct ADAS tests as well as the evaluation and post processing of the test data. The tests are run either on our in-house test track or in cooperation with external facilities.

Build-up and management of test fleets

Testing and validation of ADAS systems requires countless kilometers on the road – and many test vehicles. Building and managing such large test fleets is very time-consuming.

Our team equips the test vehicles with radars, lidars, cameras, computers and data logging. We configurate and calibrate the test equipment and implement continuous improvements throughout the project. Furthermore, we operate test drives, conduct the data collection and provide worldwide support and logistics.

ADAS component and system testing

For reliable function under all circumstances, ADAS systems depend on the smooth interplay of many components. Besides tests of individual ADAS components, Hardware-in-the-Loop (HiL) tests are indispensable for system validation in early development phases. Besides Domain HiL testing, we also operate Repro HiL tests for camera, LiDAR and radar on rigs supplied by our partner network.

Human-Machine Interface

An HMI solution that matches your expectations and those of your customers

The rise of digitalization is seeing software and HMI become more and more important. A trend that is steadily growing is the fact that autonomous driving will also mean that, in the future, passengers will have time to use even more features while driving. Smartphones, tablets, and similar gadgets are already raising customer expectations in terms of usability. More and more, the user experience in the vehicle is acting as a way to boost recognition and differentiate it from other systems and vehicles and make the proprietary brand stand out.

We support you in successfully developing your HMI solution. As an established automotive group with more than 120 years of experience, Magna has long since developed an eye for the "big picture". Building on extensive expertise, the latest technologies, a reliable network of suppliers, and engineering centers around the world, we can provide you with holistic support in the area of Human Machine Interface.

Holistic HMI competence

Customers receive a turnkey package – from the development of the idea, concept, and design, to the industrialized product adapted to their specific requirements. The focus is on a user-centered design throughout the entire process, and user experience assessments ensure comprehensive testing. Agile project management and virtual methods make the development process more efficient and help to implement improvements quickly.

Software development for display systems

Magna’s experienced development teams create HMI software and innovative operating concepts for all types of displays and control systems. We cover the entire development process from the idea through to serial production.

Rapid prototyping with AR and VR technologies saves time and money right from the early phases of development.

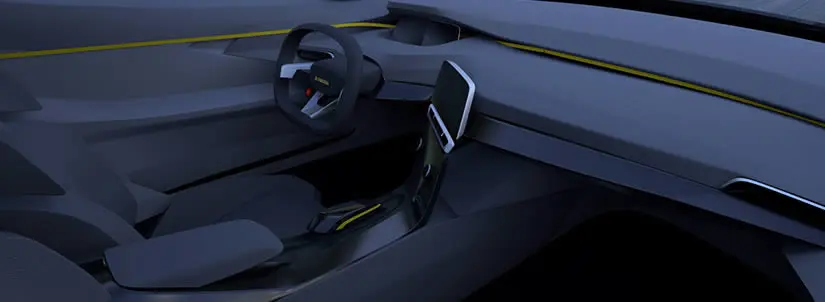

Virtual prototyping

Developing operational concepts for vehicles requires user feedback – the earlier, the better. With our virtual prototyping, it is possible to evaluate interior concepts and ergonomics using AR and VR in the early phases of development without the need for physical prototypes.

The result: quicker and cheaper implementation of improvements and earlier decisions in the development process save time and money.

Development of user solutions with AR and VR

We help companies modernize and improve their efficiency by implementing specific solutions using AR and VR.

Our team supports the customer throughout the entire product development process, from the idea to production.

The benefits: increased efficiency thanks to process optimization using AR and VR technology and cost savings due to improved efficiency and less material requirements.

Developing Modules & Systems

From Concept to Series Production

With our many years of experience in developing and manufacturing vehicles, you can count on us to understand exactly what you need and produce a product to meet your individual needs. Integrating modules and systems to meet geometrical and functional requirements is part of our core expertise, and so are the systems used to test them. Our efficient project and process management procedures make sure everything runs smoothly and that your finished product meets all your targets when it comes to cost, functionality, weight and technical requirements.

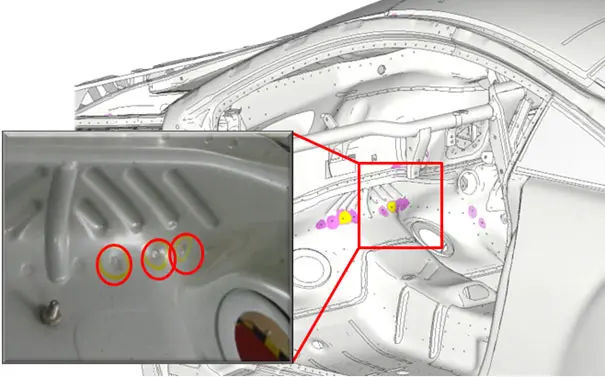

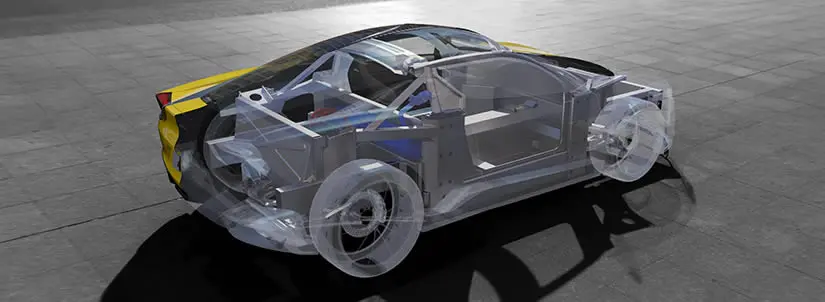

Body-in-white

The body-in-white is the main structure of the vehicle. We provide our customers with a variety of solutions to reduce the weight of the vehicle body, create synergies for derivatives, and reduce costs. The drive to reduce CO2 emissions using lightweight design is a key trend in the automotive industry, and we are keeping pace thanks to a range of innovative, lightweight solutions suitable for mass production and high volumes, all developed using virtual design technology and in-house testing equipment. Our many years of expertise in developing complete vehicles, together with our proven engineering tools, makes us the provider of choice for a broad spectrum of engineering services and production technologies.

Exteriors & Interiors

We pay special attention to the technical aspects of vehicle exteriors and interiors. From headlights to the cockpit interior, vehicle stylists need to know every detail of the parts available to them. Moreover, those parts have to do more than just look good: they also have to comply with complex functional requirements and meet customers’ expectations of high quality and a premium feel. You can rely on Magna every step of the way, from the initial design to implementation - and we are experts in managing interfaces and suppliers, too.

Chassis & Powertrain

We develop chassis and powertrain systems from initial concepts right through to mass production. We can develop and integrate entire systems, either independently or working together with external suppliers. Our core expertise includes the geometrical and functional integration of chassis, powertrain and fuel systems, as well the procedures for testing them against the requirements for the finished vehicle.

Platform Solutions

Bringing your e-vehicle to market while saving time and money

Launching an electric vehicle requires not only an innovative vehicle concept, but also high levels of investment in new technologies, staff, and production facilities. Increasing cost pressure caused by stringent government regulations coupled with slowly rising sales figures for electric vehicles are contributing to the fact that stand-alone development and production are not profitable for many vehicle concepts.

With Magna, automakers have a leading international partner in Platform Solutions. With an eye for the complete vehicle, Magna has been involved in electric mobility for 30 years and has also been working on its platforms for a considerable time. Based on a global supplier network, a Magna EV platform has been developed and industrialized, and several platform-sharing solutions have been implemented.

.tmb-product@2x.webp?sfvrsn=703234b9_2)

Three platform solutions tailored to your requirements

As a Complete Vehicle Solutions Partner, we support our customers with three platform solutions. Option one is that customers can use their own platform – developed in cooperation with Magna, if required. Option two is following the time and cost-efficient approach of platform sharing. After selecting from our network of available options, we can help with adapting the platform to fit the desired structure and requirements. What’s more, we can also provide support with connecting customers for a potential partnership. Finally, option three is using the customizable Magna EV platform. Magna takes overall responsibility for each approach, including all processes from development to industrialization.

.tmb-product@2x.webp?sfvrsn=703234b9_2)

Magna EV platform

The Magna EV platform is already validated and industrialized with a set of reliable suppliers and partners.

- C/D segment platform

- Applicable to global markets

- Five-star safety rating

- Aluminum underbody structure

- Front suspension: McPherson

- Rear suspension: Multi-Link

- Further derivatives to follow

Powertrain Engineering

World-Renowned Engineering Services under One Roof

Magna’s Engineering Services Department is a world-renowned specialist in vehicle engineering, powertrain systems, alternative propulsion systems, application software, and a full range of testing services.

Powertrain technology will continue to develop rapidly in the future. Automation and electrification have become increasingly important in recent years, and efficient automatic transmissions are every bit as important to the powertrain as electrified on-demand systems. We focus on the technologies of the future, with a strong emphasis on applying our deep knowledge of electrification and associated systems.

Bundled Systems Expertise

Powertrain technology will continue to develop rapidly in the future. Automation and electrification have become increasingly important in recent years, and efficient automatic transmissions are every bit as important to the powertrain as electrified on-demand systems. We expect to see fast growth in 48 V mild hybrid drive systems and plug-in hybrids, enabling 100% electric driving in zero-emissions zones. At the same time, the performance and torque provided by the latest vehicles will keep on increasing. The vehicles of the future will need architecture that can put that power onto the road reliably and efficiently. In addition to efficient transmissions, Magna is also investing in advanced all-wheel-drive systems to reduce energy consumption and emissions.

Prototyping & Low-volume Manufacturing

Your Concept is Our Challenge

Magna‘s prototype shop manufactures concept vehicles, test vehicles and prototypes for all stages of the design process, as well as highly-customized, low-volume finished vehicles and parts. We aim to achieve proof of concept for mass-production and new technology at the prototype stage, before the finished parts/vehicles go into production. We also carry out on- and off-road vehicle reliability and component testing.

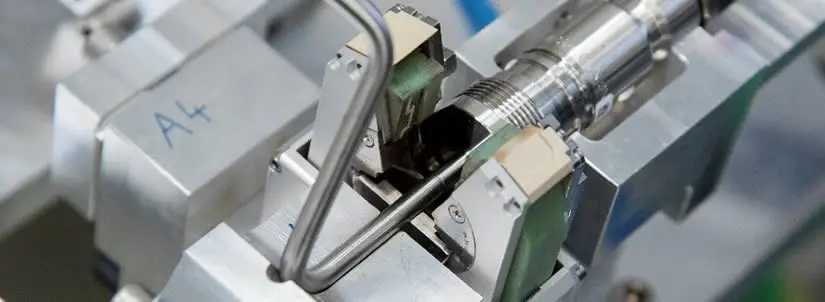

Jigs/Fixtures & Automatization

We supply turnkey solutions ranging from bespoke designs and jigs to fully-automated fixtures and robot cells, and from overall location and clamping concepts to CAD-design, assembly, measurement and adjustment. Our virtual feasibility testing, reusable standard fixtures and offline and online systems for programming robots all help to save time and money.

Sample Shop

We manufacture parts from one-off pieces through to low volume production. We can provide a uniquely flexible range of rework center activities to meet your needs, including standard material application and body cutting, and our range also encompasses physical mock-ups, seating bucks, complete concept vehicles and test mules.

Body Shop

To make sure mass-production runs smoothly, we produce top-quality prototypes. We make use of a wide range of bonding techniques for steel and lightweight joints used in existing automatic cells, including laser welding, self-pierce riveting, clinching, friction element welding, flow drill screwing, flow push and more. We also provide customized manual processes and automation for prototypes and low-volume production.

Prototype Assembly

We assemble prototypes and individual vehicles (including after-market rebuilds and low-volume production). We can also strip down and inspect vehicles, as well as auditing assembly sequences, production processes and assembly staff training.

Logistics, Maintenance, Quality

We make sure that all parts are in the right place at the right time and that the parts you need are available at every stage of your operations. Our quality checks, thorough documentation and comprehensive records at every step of the process make sure everything fits together seamlessly.

Component Testing, On- & Off Road Vehicle Durability & Misuse Testing

Component testing includes static bending and torsion, door lowering, angular and dent stiffness tests, durability tests on doors, covers and caps, vibration testing and DVP&R, as well as test tracking. We draw up test procedures, run on- and off-road tests, perform misuse tests, and document the results.

Take the 360° virtual tour for exclusive insights into our prototype shop!

Vehicle Safety Testing

From HV Batteries to Components and Complete Vehicles

Vehicle safety has improved enormously in recent decades and it has become a must-have for successful vehicle sales. Both active and passive safety systems require thorough testing before the start of series production. Furthermore, alternative propulsion systems and increasing digitalization pose new challenges to vehicle safety and security. An increasing number of derivatives on global vehicle platforms strain testing capacities for established vehicle manufacturers, whereas many new entrants have no testing facilities yet.

Magna is your partner for vehicle testing with long-standing complete vehicle expertise. From safety testing to ADAS testing right through to comprehensive high-voltage battery testing, we offer flexible and tailor-made services. In addition to custom-made test benches for specialized requirements, we also certify and test dummies.

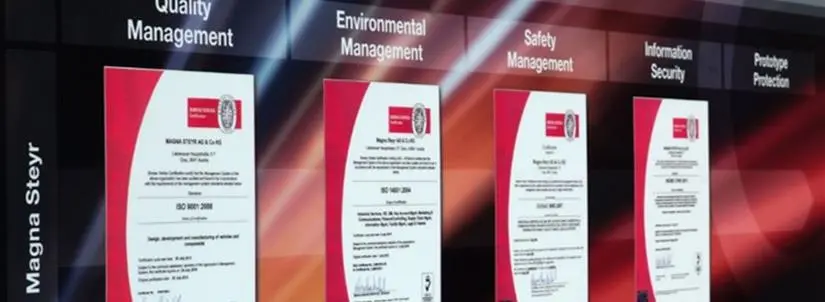

The tests are carried out in the independent and impartial test laboratory of ACTS GmbH & Co. KG, a wholly owned subsidiary of Magna Steyr. ACTS is accredited as a testing laboratory in accordance with DIN ISO 17025 and its TISAX certification ensures the highest level of information and prototype security.

Crash-Testing Finished Vehicles

Crash-testing the finished vehicle is the final step when testing vehicle safety systems. Since this crash test requires huge resources in terms of equipment and measurement technology, it is one of the most complex and expensive tests carried out anywhere in the automotive industry. Our range of tests includes the full range of frontal, side and rear impact testing, along with rollover tests. All our testing complies with international standards (ECE, FMVSS, NCAP etc.).

Sled Crash-Testing

In this simulated crash, an adapted test vehicle (either a vehicle body or a test frame) is attached to a test sled and subjected to the forces it would experience in a real impact. The big advantage of this test is that it doesn’t destroy the test vehicle, which can be used multiple times to test individual components or systems, such as seat-belts, batteries and seats.

Battery Lab

Our battery test laboratory is just one of the facilities that make up our comprehensive test center, where we test the safety, reliability and performance of electrical energy storage systems. We put them through a range of exacting test procedures to make sure they pose no risk to the occupants of the vehicle or to the environment, even if the worst happens. Our testing procedures cover everything from road safety approval tests to lifecycle testing, mechanical and electrical misuse tests, environmental testing and more.

Test Technology

We specialize in bespoke testing to meet customer requirements, including designing test benches and providing crash dummies, so you can count on us whenever you need a fast, flexible solution. Our engineers can draw on years of experience to deliver customized, turn-key test benches and install them as part of customers’ production processes.

In addition, we can certify crash dummies and crash-testing rigs. Our flexible pick-up and delivery service ensures our customers can use their kit whenever they need it.

Component Testing

Magna tests safety, functionality and service life using specially designed equipment. We cover everything from individual components through to complete vehicles, and perform all standard safety, reliability, strength, function, stiffness and environmental simulation tests in accordance with applicable legislation and/or specific customer requirements.

Take the 360° virtual tour for exclusive

insights into our safety testing facilities!

Aerospace

The Reliable Partner for the Global Space and Aeronautics Industry

Propellant Lines for Launch Vehicles

Parts used in propulsion systems for space launch vehicles have to stand up to the most extreme operating environments. Anything less than the highest possible standards of design and manufacturing can put the mission in jeopardy. Magna has been working with cryogenic propellant lines since the 1990s. As a development and manufacturing partner for the Ariane 5 program, Magna played an active role in one of the most successful launch vehicle programs in history. We have delivered everything from small, high-pressure helium lines to large-diameter feed lines for liquid hydrogen (LH2) and liquid oxygen (LOX), made from stainless steel, nickel-based alloys, aluminum and titanium. Our state-of-the-art welding and non-destructive inspection (NDI) processes, combined with highly trained and experienced personnel, ensure that we deliver a high quality product every time.

We also operate clean rooms, precision cleaning facilities and labs, as well as specialist facilities for molding foam insulation parts for propellant lines.

Flexible Elements

Launch vehicles and airplanes are exposed to extreme operating environments. Their piping systems and ducts have to be flexible enough to deal with a wide range of loads, displacements and temperatures. Magna has the in-house expertise to develop and manufacture flexible components, including flex-joints, gimbals and compensators, complete with metal bellows.

Our components are individually designed according to customer requirements, and we manufacture them in-house using a full range of special processes. One of our outstanding innovations is our Aluminum Compensator (featuring a gimbal and an Angular Axial Compensator). With the support of ESA’s Future Launchers Preparatory Programme, Magna developed, built and tested a compensator featuring an aluminum structure and stainless steel bellows to TRL level. This new technology can be combined with aluminum propellant lines to reduce mass by 30% compared with conventional compensator assemblies.

Tubes and Ducts for Aircraft

Magna supplies the aeronautics industry with metallic piping and ducting systems. Our extensive experience in manufacturing welded fluid conveyance components is trusted by a host of renowned aerospace companies. This type of equipment requires a thorough knowledge of manufacturing processes, as well as effective project management.

Our capability encompasses all kinds of metallic pipes and ducts, from bleed air to fuel and hydraulics. Magna has gained multiple customer approvals for manufacturing and special processes. Magna Aerospace has been certified under EASA Part21 G (Production Organization approval) since 2015, and is authorized to ship parts using EASA Form 1.

Piping for Alternative Fuel Systems

Alternative fuel systems using substances like compressed natural gas (CNG) or hydrogen (H2), operate under high pressures from 260 bar (3,770 psi) to 700 bar (10,150 psi). Handling highly-pressurized gases like these safely requires stringent quality checks on the production line and advanced cleaning processes to ensure all the associated components, including valves and regulators, are working perfectly.

Meeting these demanding requirements is all in day’s work for our aerospace specialists, and our expertise in this area also means we can also provide major synergies for our automotive customers. Processes we offer include CNC bending, welding, fitting, assembly and cleaning, as well as pressure and leakage testing.

Gas Storage Systems

Magna is the world leader when it comes to manufacturing liquid hydrogen (LH2) tanks for mobile applications, and we were the first company to put a liquid hydrogen tank for automotive applications into small-scale production. We have gone on to transfer this unique expertise into R&D programs for liquid hydrogen systems in aircraft, and hydrogen could well prove key to the mobility solutions of the future. Our current range of expertise covers development and prototyping through to small-scale production.

We are also working on propellant tanks (Composite Overwrapped Pressure Vessels, or COPVs) for satellites. We aim to transfer our automotive pressure vessel technology into the space market, thus providing an optimum cost-to-performance ratio for future spacecraft.

Quality System / Certifications

Magna Steyr Aerospace has established a very robust management system that complies with all of the following norms and standards:

- EN 9100 Quality management systems for aerospace

- ISO 3834-2 Quality requirements for welding

- EASA Part 21 G Production organization approval

- ISO 14001 Environmental management system

- OHSAS 18001 Operational safety management system

- ISO/IEC 27001 Data security management system

We also hold several active customer approvals for manufacturing and special processes. Including from Ariane Group, Boeing (D1-4426 Approved Processor) and MTU Aero Engines.