Control Modules

Driving the Transformation Toward Electrification

Magna is one of the preferred partners for all electrified systems. With our extensive experience and innovative technologies, we are driving the transformation towards electrification in the automotive industry. Magna’s electronic products include electronic inverters, ECUs, e-pumps and power closures. Our complete system expertise is based on a unique combination of engineering and development know-how to drive as efficiently and economically as possible. At Magna, we are committed to environmental protection, vehicle efficiency and new mobility concepts to increase the quality of life around the globe.

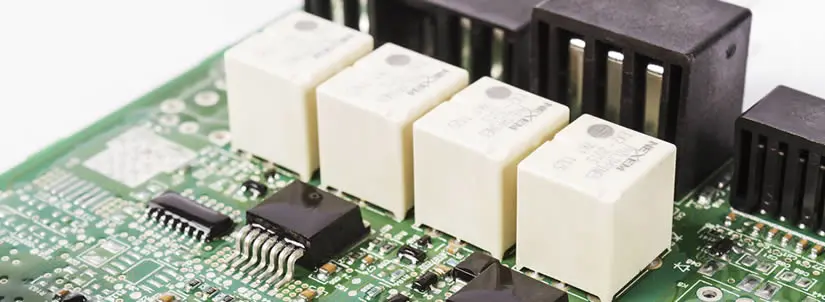

Chassis Control Modules

Magna Safety and Control

Magna’s Chassis Controller and Battery Management Systems provide special functions like active damping and suspension control as well as monitor and control battery packs for safe operation in response to vehicle conditions and thermal requirements.

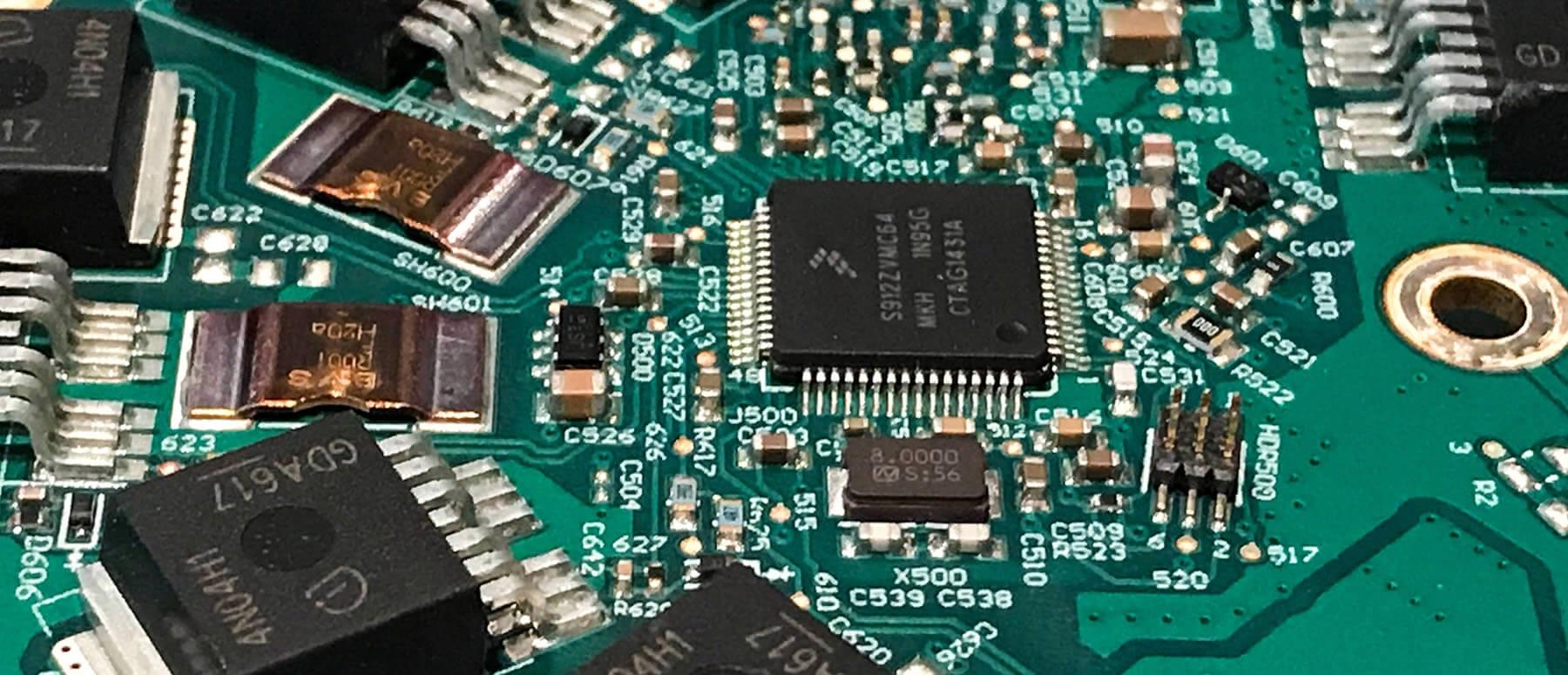

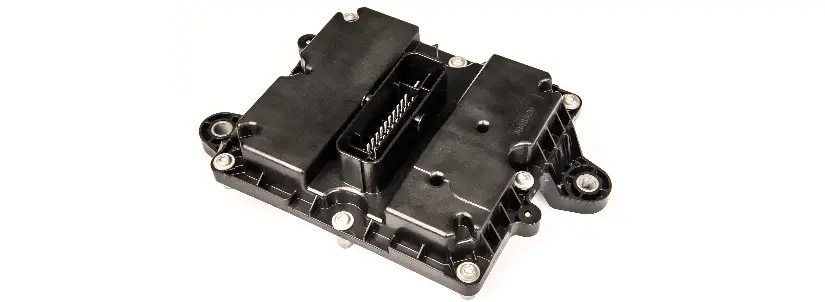

Intelligent Chassis Control Module (ICCM)

Magna's Intelligent Chassis Control Modules (ICCM) perform various suspension and chassis related functions with full ASIL D functional safety capability. System integration include mounting outside the passenger compartment usually to a rigid body.

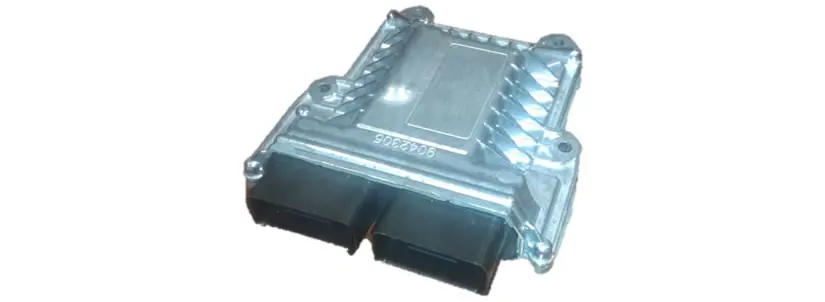

Battery Management Unit

Magna Powertrain offers a highly-integrated eDrive system, which contains gearbox, emotor, inverter and a torque vectoring option, additionally a decoupling and park lock option can be applied.

It provides up to 160kW for 30sec and up to 4,000Nm at the wheels. The eDrive system fulfills the ASil "D" safety integrity level. It can be applied to both hybrid and battery electric vehicles.

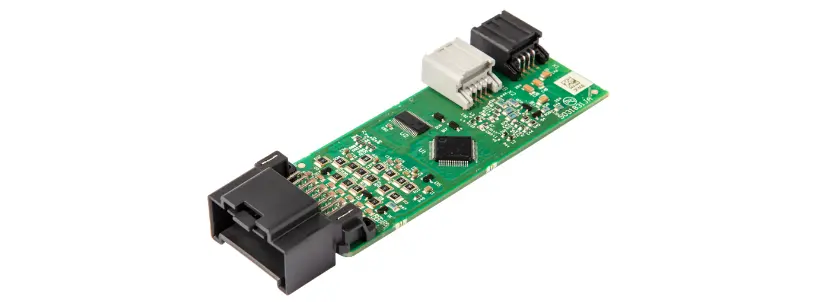

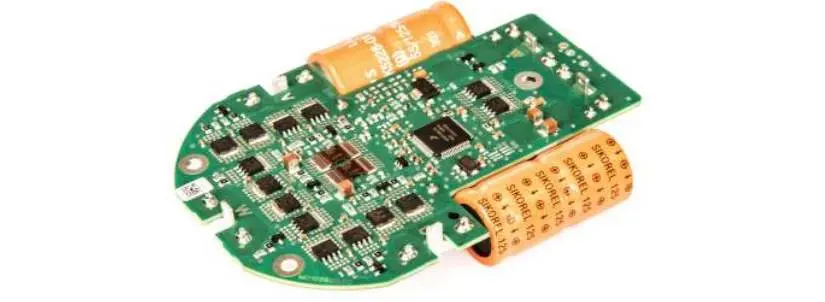

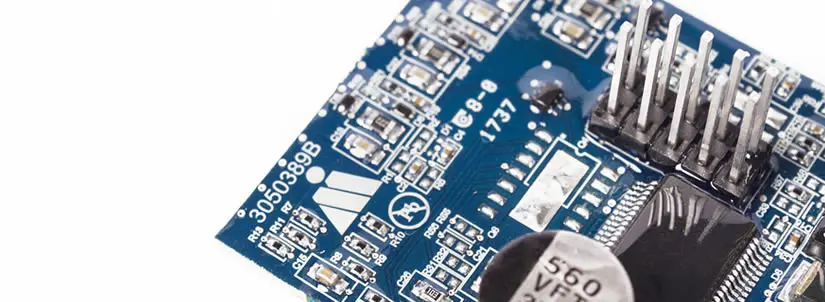

Cell Sensing Board (CSB)

The CSB measures four temperatures and up to 12 Lithium Ion or Polymer battery cells. The data can be polled by another module in the system (usually a Battery Management Unit). In addition, the CSB has hardware protection against over- and under-voltage as well as over temperature.

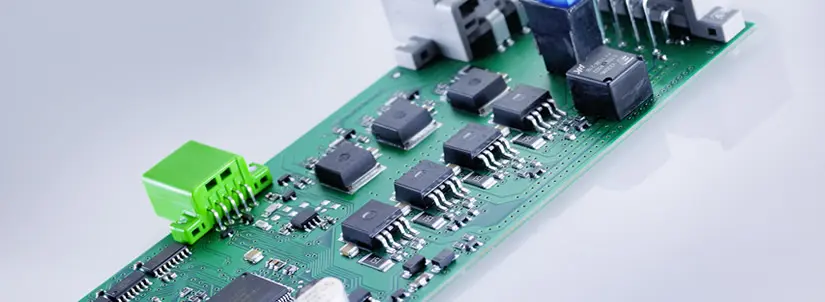

Glow Plug Control Modules

Flexible Control with Magna

Magna's external control unit for glow time regulation is a flexible solution able to either controls glow plugs or control additional functions like auxiliary heating, water level sensors or filter heating.

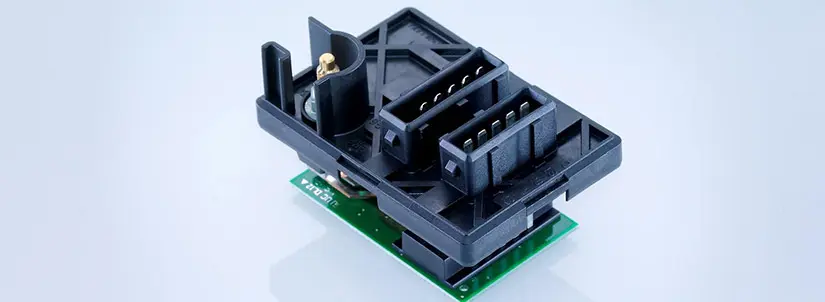

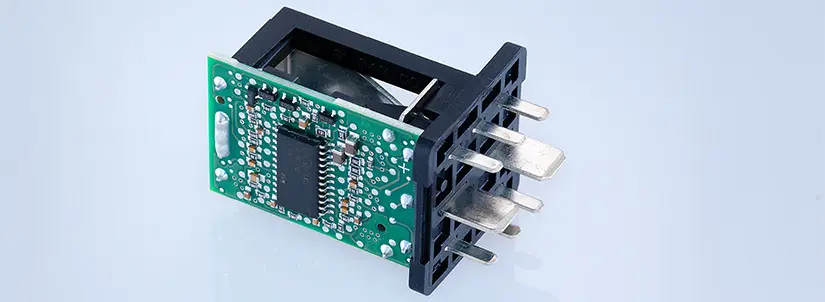

Glow Plug Control Unit (GPCU)

Magna offers an external control unit for glow time regulation. This unit either controls glow plugs only or integrates control of additional functions like auxiliary heating, water level sensor or filter heating in one unit. This product is designed for three, four and five cylinder engines.

Main Features and Technical Advantages

Magna’s glow plugs have many advantages, including having a customized ASIC or control unit design. Compatible with European On-Board Diagnostic (EOBD), these are also EU5 / EU6 compliant. Various communication protocols are possible, and the glow plugs have central or single thermal overload protection while ensuring a compact design for optimized vehicle packaging.

Powertrain Control Modules

Controlling the Torque

If it’s controlling the torque at the rear wheels of the vehicle, balancing and shifting when needed; or reducing power absorption, our technologies result in better efficiency and less environmental impact.

Transfer Case Control Module (TCCM)

The TCCM provides complete torque control from rear-to-front and front-to-rear wheels. It is mounted with the transfer case, able to perform diagnostics and provide status and compensate for ambient temperature variations to improve quality and reliability.

Rear Driveline Control Module (RDCM)

Magna's RDCM controls the torque at the rear wheels of the vehicle balancing it left to right, and shifting torque when needed.

Powertrain Control Module (PCM)

Functions as the master controller in hybrid and electric vehicles. It is responsible for reading driver input and determining the required wheel torque, while also monitoring safety systems and providing thermal and energy management.

Brushless DC Motor Controller

Magna’s BLDC motor control platform is designed to efficiently control motors for air, oil, and water pumps in the power range of 80W to 600W. This modular platform includes a complete selection of hardware options and motor control algorithms to fit almost any automotive application.

Mechatronic Control Modules

The Brains Behind Mechatronics

Electronics enable advanced technologies that open up new ways of interacting with the vehicle. As a complete system supplier, our in-house electronics design and manufacturing capability allow us to seamlessly integrate new features and solutions into vehicles.

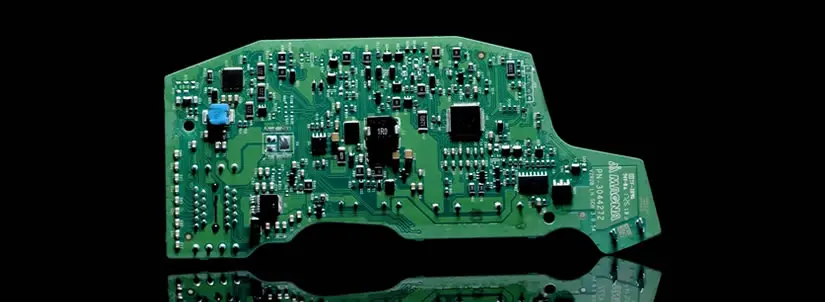

Electronic Control Units

ECUs control the function of mechatronics systems by taking input from the system and sensors and relaying commands to the mechanical components. Magna produces these in high-tech clean rooms while dedicated software development teams ensure all components communicate and operate seamlessly.

Obstacle Detection

Smart sensors ensure all of our systems operate safely and will stop if any object is detected within a pinch zone. Non-contact technologies are available which greatly increase the safety of any power closure mechanism.

Gesture Recognition

Sensors and integrated ECUs allow for new ways of interacting with the vehicle. Simply waving a hand or foot near a designated area on the vehicle can open or close any door.

Deployable Running Board (DRB) for Complete System Integration

The DRB uses vehicle input switches and CAN messages to determine if it should deploy the power running boards on large trucks. The device can operate up to two brushed motors simultaneously.

The DRB is mounted directly on top of battery cell modules, connected internally to each cell, and to four temperature sensors. Communication link is daisy chained to every module in the pack (from two to eight modules).

Power Lift Gate (PLG)

The Power Lift Gate (PLG) uses vehicle input switches and CAN messages to open the lift gate electrically on SUVs and trucks.

The PLG is mounted in the passenger compartment of most vehicles and connects vehicle CAN network to the trailer lighting system.

Trailer Control Module (TCM)

The TCM is mounted in the passenger compartment of most vehicles. Connects vehicle CAN network to the trailer lighting system. According to vehicle function, the lamps can be activated to switch on and off.

The system can also charge an on-trailer 12V battery, monitor the battery while in sleep mode, diagnose lamp failures and detect trailer connection and removal for anti-theft purposes. If CAN is lost, a "limp-home" backup is activated for safety and security.